A stitch in virtual time saves nine in real time

Time is precious to everyone. This is especially true for scientists experimenting at any one of the user facilities supported by the U.S. Department of Energy's (DOE) Office of Science. These world-class facilities can image and characterize materials down to the atomic scale. They can also track the movement of particles down to one ten-millionth of a billionth of a second.

Subramanian Sankaranarayanan and his team want to assist scientists in employing their limited time at these world-class facilities as wisely as possible. Sankaranarayanan is a group leader in the Center for Nanoscale Materials at DOE's Argonne National Laboratory and associate professor at the University of Illinois Chicago.

Each year, DOE's user facilities award instrument time to some 16,000 scientists from around the world. Instrument time is at a premium and can range from only a few hours to days. If the experiment fails for some reason, the disappointed scientist must return home and begin the proposal process again with a different approach. This process can take as long as another year.

Scientists from Argonne are working on digital twin software that will help spare experimenters from such delays. And they are developing and testing it with Argonne's own DOE Office of Science user facilities: the Advanced Photon Source, Center for Nanoscale Materials and the Argonne Leadership Computing Facility (ALCF).

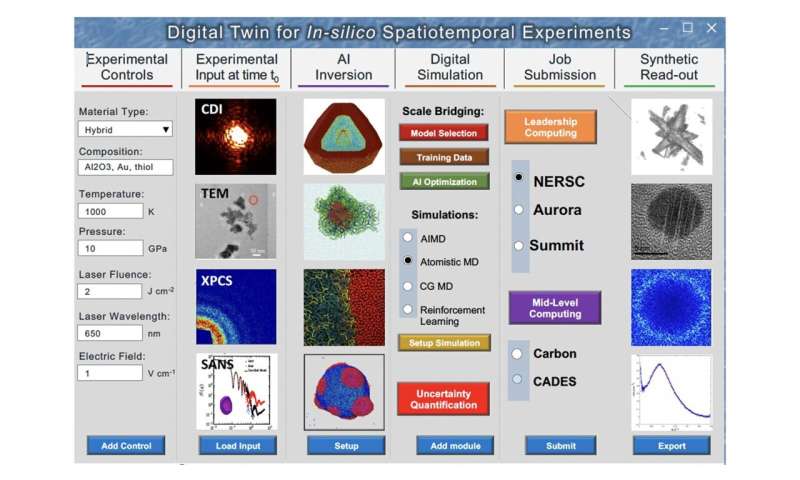

"Our digital twin is easy-to-use software that simulates the research environments that scientists will encounter at DOE facilities," Sankaranarayanan said. This software is built with artificial intelligence and machine learning and makes use of supercomputers such as the ALCF systems. Given the exhaustive sets of experimental parameters that are likely to be explored by users of a digital twin, such large-scale computing resources are essential.

The digital twin allows researchers to run a simulation under one set of conditions with regard to sample type and composition, temperature, pressure and so on. They can then view the results almost instantaneously. This will reveal what is happening with the atoms or molecules in the sample as a function of time or distance. Then, they can easily vary the conditions, run a second simulation and view a different set of results for comparison. And so on. Researchers can also test different theoretical methods for creating the simulations.

"The researchers might then conclude the simulated results are more or less as expected," Sankaranarayanan said. "Or they might find really interesting physics they did not anticipate under certain experimental conditions." Having adjusted their experimental plans accordingly, scientists would thus arrive at DOE user facilities ready to make optimal use of their allotted time.

"And even after having completed their experiments," Sankaranarayanan said. "Users can return to our digital twin and run further simulations to extend and refine their analyses of the data."

Select users are now testing the digital twin to characterize materials with several analysis methods available at DOE facilities. The team plans to further improve the digital twin and expand the capabilities into other analysis methods in the coming years.

The digital twin stands to have a profound impact on the productivity of thousands of scientists accessing DOE user facilities. They will arrive better informed about the possible impact of their experimental conditions on the expected results. They can thus take maximum advantage of the allocated time for an experiment.

"The digital twin is one of several ways scientists are employing artificial intelligence, machine learning and supercomputers to transform how research will be done in the future," noted Sankaranarayanan.

Provided by Argonne National Laboratory