Vision of the perpetual, innovative product: Circular factory to revolutionize production

Manufacturing companies in particular face the challenge to come up with economic approaches for circular large-scale production. Today, the circular economy is mainly restricted to low-wage countries where small batch series with a high proportion of manual steps are produced.

For example, in Europe, the percentage of material recycled and reintroduced into the economic cycle in 2023 is a mere 7.2 percent (see: www.circularity-gap.world/2023).

"As a society, we cannot continue to simply dispose of products that are no longer needed. To achieve long-term use of our resources, we have to move towards a circular economy systematically so that, at best, we can use products or their components perpetually. Circular economic approaches running in the same vein are the focus of the new CRC, which pools the skills of the researchers from mechanical engineering, computer science as well as electrical engineering, and information technology," says Professor Oliver Kraft, representing the President of KIT.

Vision of the perpetual, innovative product

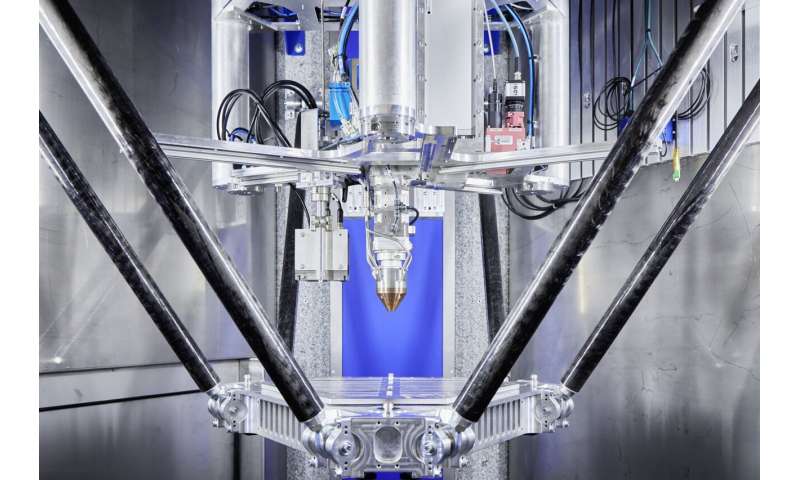

So far, remanufacturing, i.e., reprocessing of used products, was considered the method with the highest standard with regard to the quality and warranty criteria of the reprocessed products. "This is the only circular method able to compete with a new product, for that matter. The vision of a 'circular factory,' however, goes far beyond that point. It consists in enabling integrated linear and circular manufacturing of new products at an industrial scale where different products require different degrees of reprocessing," explains Professor Gisela Lanza, who heads the wbk Institute of Production Science of KIT and is a spokesperson for the CRC.

The goal of the circular factory is to upgrade used products to the state of current product generations so that we get closer to the vision of the perpetual, innovative product. Even though "perpetual" usage of a used product substance appears to be virtually impossible, the vision of the perpetual, innovative product should be adopted. Lanza compares this to the Pole Star, which represents the perfect direction towards which everything is to be oriented.

"The Collaborative Research Center 1574 marks a cornerstone in our research program for the next decade at the wbk Institute of Production Science. Our fundamental research forms the basis for the shift in the economy from linear to circular models and the capability of a circular factory to manufacture the perpetual, innovative product," explains Lanza. On this basis, she and her team want to launch numerous joint application-related projects with industry that pave the way for a sustainable and innovative future.

Range of topics and project areas

In order to explore processes and mechanisms that are still unknown, the CRC team addresses scientific issues from production engineering, product development, and materials technology, human and industrial engineering, robotics, computer science, and knowledge modeling.

The key research questions are: How can new products be generated from uniquely used products? How can its functionality be guaranteed for the second lifecycle? How can humans learn complex problem-solving strategies and how are these strategies transferred to automated production technology?

How can all this be implemented in a changeable, autonomous production system so that economic circular manufacturing of large-scale series is possible even in high-wage countries? How can data and information be leveraged to further improve the process?

The CRC is subdivided into three project areas: Project Area A will explore planning and control of the circular factory to achieve maximum value retention of unique used products for the primary market; Project Area B will devise measuring strategies for capturing, modeling, and evaluating each product state and for capturing and interpreting human process execution; and Project Area C will create an entirely modular production system that enables continuous adaptation to the latest product instance.

Provided by Karlsruhe Institute of Technology