Grid electronics research to bridge gap to cleaner, more reliable power

Scientists at the Department of Energy's Oak Ridge National Laboratory are looking for a happy medium to enable the grid of the future, filling a gap between high and low voltages for power electronics technology that underpins the modern U.S. electric grid.

Today's power electronics, which take split seconds to perform tasks such as converting the direction of current or adjusting voltages, tend to operate at the extremes. Charging personal vehicles or storing energy from a commercial solar panel requires low voltage, while high voltage is used for utility-scale projects like wind and solar farms or interconnecting power distribution and transmission systems.

But there is a power electronics gap between 1,500 and 50,000 volts—the "medium-voltage" range—that is critical to larger-scale renewable energy projects, larger equipment such as wind turbines and larger electric vehicles like trains and vertical-takeoff aircraft.

Bridging that gap will help the U.S. achieve clean energy goals and expand capacity in an overburdened power grid—without erecting thousands of miles of new transmission lines.

"There are many applications that can fit here, but the technology for that middle space hasn't been proven to be reliable or cost effective," said Prasad Kandula, leader of ORNL's Grid Systems Hardware group.

To help meet the need, ORNL will be guiding DOE's new Medium Voltage Resource Integration Technology program, or MERIT, which teams four national labs and five universities to develop devices that operate efficiently in that middle range.

Kandula notes that medium-voltage power electronics have become more affordable and making the switch could reduce the size, weight and volume of a system. "Power conversion using medium-voltage power electronics is expected to be more efficient, in addition to packing more power into a smaller space," he said.

Benefits to grid reliability, clean energy

Filling this technology gap could also address a pressing need to expand electric grid capacity for meeting today's demands and providing tomorrow's economic development opportunities.

Most of the North American electric grid uses alternating current, or AC. But renewable energy generation and electric cars require direct current, or DC. Power electronics are used to switch between these flows and to link separate systems. Expanding these capabilities to medium voltages would open new options for electric reliability.

For example, medium-voltage power electronics could be used to feed electricity from a region with extra supply to a neighboring system struggling to meet demand. This could prevent rolling blackouts, price spikes and activation of polluting backup power plants. In another scenario, medium-voltage power electronics could help convert key portions of the distribution grid from AC to DC, because DC is more efficient at carrying power long distances. This would essentially increase the amount of delivery capacity using the same power lines.

Kandula said medium-voltage power electronics could also enable complete DC operation for projects such as a microgrid with its own solar power and batteries. "Initially a DC ecosystem would most likely be used at isolated systems like a campus," Kandula said. "The next level might be a distribution feeder of a few miles, like a solar farm at the edge of the grid."

A DC-only system requires less power conversion equipment and eliminates energy losses that occur during the conversion process. It could make clean energy more efficient and economical, especially as big solar and wind farms are increasingly built far from population centers where electricity demand is concentrated.

Medium-voltage research leadership, capabilities

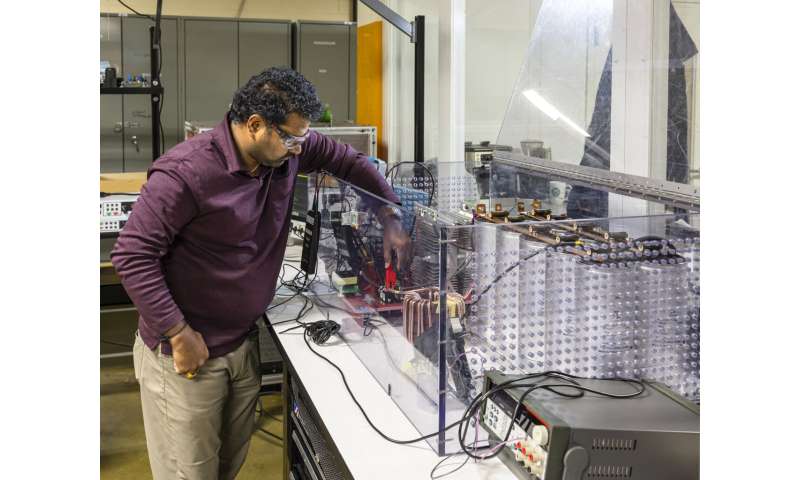

ORNL researchers have been developing a menu of medium-voltage building blocks, such as converter modules, specialized magnetics, and protection mechanisms that isolate electrical problems.

"With MERIT, we'll develop building blocks of varying types to increase reliability, then stack multiple blocks to reach higher voltages," Kandula said. The ability to plug a variety of modules into a larger architecture will make it easier to explore new power applications, from recharging long-haul electric trucks to producing green hydrogen for the steel industry.

This effort builds on the experience and capabilities in ORNL's Grid Research Integration and Development Center, or GRID-C, where researchers can simulate different architectures, build a converter and test it up to 13,000 volts.

"We are developing a matrix of technology across components that can go into many applications," said Madhu Chinthavali, head of ORNL's Energy Systems Integration and Controls Section. "ORNL's GRID-C is uniquely equipped with the component-building proficiency, test beds and expertise to fully develop and test these power electronics components."

For MERIT, ORNL will expand existing relationships with utilities to identify medium-voltage needs. This builds on the Power electronics Accelerator Consortium for Electrification, or PACE, initiative that was created in 2022 to increase collaboration among research institutions, power companies and manufacturers. An initiative of DOE's Office of Electricity, PACE is adding partners to take innovations rapidly from the lab to the electric grid.

Individual labs can join forces with industry to pursue specific advances in medium-voltage power electronics. "The end goal for us is to pick a use case, work with a partner, build a full system, install it, show it operational in the field and show the financial implications," Kandula said.

Provided by Oak Ridge National Laboratory