Making hydrogel bioelectronics at room temperature

Researchers at the University of California, Los Angeles have taken a major step in enabling direct fabrication of hydrogel bioelectronics within tissues.

Due to their structural similarities with biological tissues, organic conducting polymers have been widely used in biological applications, namely, organic bioelectronics. Although various organic bioelectronic devices have been developed, most of them rely on mechanically brittle conducting polymer films. Mechanically softer conducting polymer hydrogels are considered as more promising candidates to develop advanced organic bioelectronics. Their superior biological and mechanical compatibility with tissues makes it possible to better suppress immune responses, which is highly desirable for the diagnoses and treatment of chronic diseases.

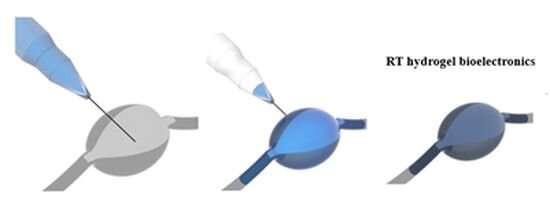

A distinct advantage of organic electronics over inorganic electronics is their low-temperature processability. However, most conducting polymer hydrogels are still synthesized at elevated temperatures. Thus, they cannot be directly manipulated in tissues. To circumvent this issue, UCLA scientists have proposed a concept of "room-temperature hydrogel bioelectronics" (RT hydrogel bioelectronics). RT hydrogel bioelectronic devices are, as indicated, completely fabricated at room-temperature. Therefore, they can be easily deployed in situ within tissues, promoting their use in more in vivo applications.

The key to realizing RT hydrogel bioelectronics is the development of RT hydrogels. This was achieved by introducing additional ions into the conducting polymer poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) suspension. When the ionic strength in the PEDOT:PSS suspension reached a threshold level, RT-hydrogels formed spontaneously. The mechanical properties of the RT-hydrogels could be tailored by constructing an interpenetrated structure in which a second, harder hydrogel, which was also formable at room temperature, was used to improve the mechanical strength.

RT hydrogel bioelectronics enables many new applications:

- Injectable conducting hydrogels: Simply by injecting the ion-mixed PEDOT:PSS suspension into an artificial tissue, RT conducting hydrogels formed spontaneously without any external stimulation. Injectable conducting hydrogels can be applied in minimally invasive surgeries such as nerve regeneration and spinal cord repair.

- Conducting hydrogel fibers: When the suspension was injected into a hollow tube, hydrogel fibers formed spontaneously. These fibers could be extruded simply by pressurizing the tube. This technique enables the production of 3-D macroscopic hydrogel fibers, which otherwise would not possible with existing fiber spinning technologies. These hydrogel fibers were further used to develop hydrogel transistors, demonstrating their potential to be applied in functional hydrogel bioelectronic devices.

- Water-healable soft conductors: These RT hydrogels exhibited excellent volumetric swelling properties, making them a promising candidate for developing water-healable soft conductors.

"We believe this is just the beginning of a new era of hydrogel bioelectronics," said Shiming Zhang, a postdoc researcher in Prof. Ali Khademhosseini's lab at UCLA. "We have demonstrated it is possible to fabricate various hydrogel bioelectronics devices directly in tissue with these unique RT hydrogels. However, we have not yet evaluated their efficacy in animal studies. To meet the critical need for clinical translation, many parameters need to be further optimized, such as conductivity, biocompatibility and mechanical stability. But we are confident in the scientific community's ability to realize these ambitions."

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Shiming Zhang et al. Room‐Temperature‐Formed PEDOT:PSS Hydrogels Enable Injectable, Soft, and Healable Organic Bioelectronics, Advanced Materials (2019). DOI: 10.1002/adma.201904752