No such thing as nonlinear resolution in ultrafast laser machining

This year, we celebrate the 60th birthday of the laser. Its inventor, Theodore Maiman, once famously called it "a solution looking for problems," a judgment that has been soundly contradicted over the decades, as demonstrated by the vast applicability of laser technology in diverse fields.

One of those fields routinely using lasers is precise material modification, including such diverse applications as eye-refractive surgery and 3-D microstructure fabrication. In particular, the use of ultra-short pulses (less than a picosecond long) provides unprecedented fabrication quality and reproducibility. As a unique characteristic, intense, ultra-short pulses can process any type of material, even those that are transparent to incident light, due to nonlinear absorption at the extremely high peak powers reached with ultrashort pulses.

The confinement of nonlinear absorption has proven to be crucial for resolution purposes in so-called multiphoton microscopy techniques, even overcoming the limits of diffraction. Our intuition, then, led the laser machining community to associate the same resolution benefits when inducing material modifications with ultrafast light.

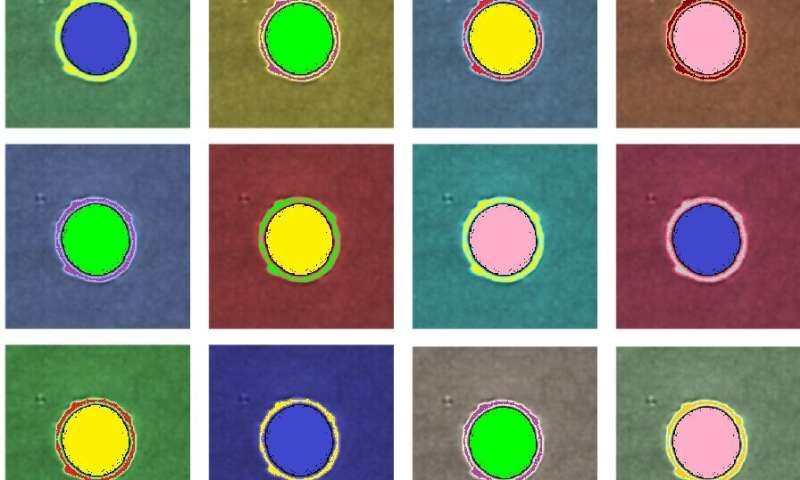

However, we have experimentally revealed that the concept of multiphoton resolution used in microscopy does not hold for laser-induced material removal or ablation. Unlike fluorescence, observed in multiphoton microscopy, ablation is not directly proportional to absorption. Ablation is an effect that occurs when surpassing a given absorbed energy, or in other words, when the incident beam intensity locally exceeds a required threshold. Thus, resolution is predicted exclusively from the incident beam without the need to account for the nonlinear nature of absorption.

We believe this represents an important finding because over decades, femtosecond laser machining has taken the opposite direction to lithography in the spectral domain. However, these are two fabrication methods on which the same optical limits ultimately apply. On the lithographic front, sub-20-nanometer resolution is routinely achieved with the use of extreme UV illumination. On the laser front, high precision is still based on ultrafast lasers emitting in the near-infrared. Despite similar resolutions that have been demonstrated in laboratories with both methods, laser machining falls short in providing a practical solution for nanofabrication. There has probably been no technological disruption in the field because the misconception that we tackle today has associated high resolution to strong nonlinearities, and thus long wavelength. We believe this provides a new vision that opens a unique possibility to re-route femtosecond laser machining in the quest for the nano-resolution required for such applications as nanosurgery of DNA and to tailor solid surfaces with unprecedented control.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

M. Garcia-Lechuga, O. Utéza, N. Sanner, and D. Grojo, "Evidencing the nonlinearity independence of resolution in femtosecond laser ablation," Opt. Lett. 45, 952-955 (2020) doi.org/10.1364/OL.382610

Bio:

Dr. David GROJO is CNRS researcher at LP3 laboratory a research unit joint with Aix-Marseille University. He obtained a French MSc in 2002 after a full year abroad study at CREOL - Center for Research in Electro-Optics and Lasers in Florida (USA). After a PhD at Aix-Marseille University, he has worked as Postdoctoral Fellow at the Attosecond Science Laboratory in Canada. Todays researches of David GROJO concentrate on extreme space-time confinements of light for material modifications. Among other things, he studies nonlinear processes with non-conventional radiations. This opens new and exciting opportunities to tailor material properties with nanometer-scale spatial resolutions and in the three dimensions (3D) for materials inside which the occurrence of breakdown is, today, hardly accessible (e.g. semiconductors).