Testing a transparent superhydrophobic coating on face shields for enhanced protection against COVID-19

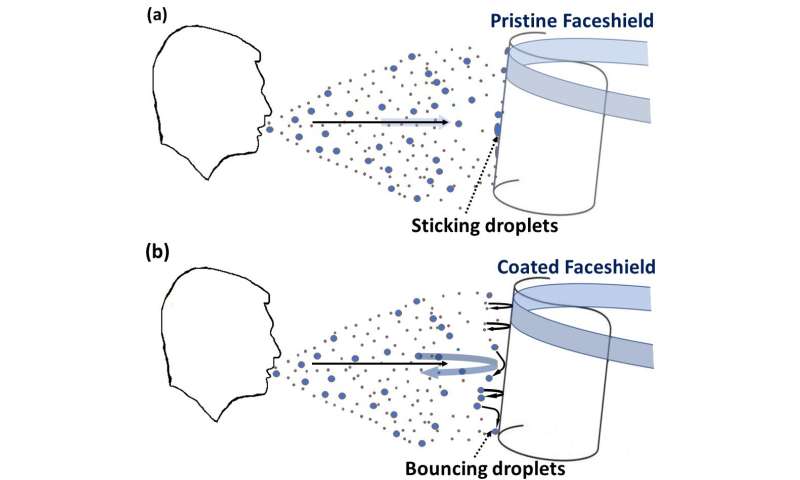

A face shield is personal protective equipment to prevent airborne transmission of COVID-19. These face shields are made of polyethylene terephthalate (PET), which is hydrophilic. The respiratory droplets exhaled by an infected individual can stick to the face shield surface, and the surface may remain contaminated with the virus for days. Individuals who accidentally touch such surfaces are susceptible to infection by fomite transmission, which calls for frequent cleaning and sanitization.

This situation is more likely to happen where physical proximity becomes unavoidable, such as in an airplane cabin, elevators, and hospital premises. Further, it could get wet in the rain, and moisture condenses, reducing the user's visibility. Hence, our goal was to improve the effectiveness of a face shield to make it non-sticky against respiratory droplets.

Interaction of droplet and face shield

Typically, the respiratory droplets are tiny—their sizes are about 5–200 microns. When droplets fall on a surface, the kinetic energy and surface tension of the impacting droplet tends to flatten the droplet and spread it over the surface before it recoils. If the surface has a greater affinity towards water, i.e., high wettability, as in the case of the PET surface of the face shield, the impacting droplets may stick to it after the impact.

For a non-wetting or hydrophobic surface with a lower affinity to water, the impacting droplets rebound from the surface after the recoil, leaving behind a dry surface. The static friction on the surface plays a vital role in dictating the criterion for the rebound. It also determines whether an impacting droplet would slide down from an inclined surface under gravity. The contact angle hysteresis characterizes the friction. A combined effect of wettability and contact angle hysteresis on the droplet bouncing and sliding phenomena was unknown. We investigated this scientific problem and applied the concept to design a better face shield to combat COVID-19.

Silica nanoparticles coating

To prevent the respiratory droplets from sticking to the surface, we proposed a technique to enhance the effectiveness of the face shields by coating them with a transparent alcohol-based suspension of silica nanoparticles. The resulting coated surface becomes superhydrophobic with low hysteresis, which repels the airborne respiratory droplets laden with a virus; an impacting droplet bounces and rolls off the surface at any inclination angle. Thus, this coating will keep the shield safe from disease transmission.

Testing face shields against surrogate water droplets

We performed experiments on the coated and non-coated face shield by impacting water droplets on it to show how the individual droplets behave after coming in contact with the face shield. We captured the process with high-speed, high-resolution videography. Further, we developed an analytical model to predict the water repellent behavior of the surface, which agrees well with our experimental results. To expand the usability of our results, we have also performed droplet impact at a different angle and impact velocity to map with realistic scenarios. For the first time, our work demonstrated the combined role of hydrophobicity and contact angle hysteresis on the droplet bouncing phenomena. Based on these two parameters, we also presented a regime map of the bouncing/non-bouncing effect. Thus, the present results may be applicable beyond the coating material chosen in the current work.

Bouncing and non-bouncing droplets on the face shield

We observed that the coated surface has lower wettability and contact angle hysteresis than the non-coated surface. The droplets bounce off the coated surface in all cases of surface inclination, achieving the desired performance of the face shield to repel the respiratory droplets. This is explained by the fact that the droplets experience lesser energy loss and overcome the contact line friction (low hysteresis). The droplet has enough energy to rebound from the surface. We also changed the impact velocities from 0.1 m/s to 1.4 m/s to account for all the realistic scenarios of respiratory events and weather conditions that potentially contaminate a face shield. In this case, the face shield repels the droplet, and the face shield's visibility remains unaffected in rainy and foggy weather.

In closure, our work published in Physics of Fluids could help fabricate more effective personal protective equipment in the COVID-19 era to prevent the infection from spreading. This modified face shield is essential for frontline health workers and public service employees to protect them from catching the disease.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Bibek Kumar et al, Evaluating a transparent coating on a face shield for repelling airborne respiratory droplets, Physics of Fluids (2021). DOI: 10.1063/5.0073724

Bibek Kumar and Sanghamitro Chatterjee are a Ph.D. student and a Postdoctoral fellow, respectively, in the Mechanical Engineering Department, I.I.T. Bombay, Mumbai, India. Amit Agrawal and Rajneesh Bhardwaj are Professors in the same department.