Scientists reverse notorious role of hydrogen in steel

Hydrogen has been known to be detrimental to steels since 1875. Just a few ppm of nascent hydrogen can cause large and harmful changes in the properties of steels, known as hydrogen embrittlement (HE) or hydrogen-induced delayed fracture. In fact, many notable failures in history have been attributed to HE. Hydrogen also limits the applications of newly-developed advanced high-strength steels. One classic example is twinning-induced plasticity (TWIP) steel. This steel, whose plasticity is enabled by deformation twins and dislocation glide, exhibits high strength and very large ductility. However, TWIP steel is prone to HE, and this flaw limits its potential applications, particularly in automobiles.

Unexpected discovery from hydrogen

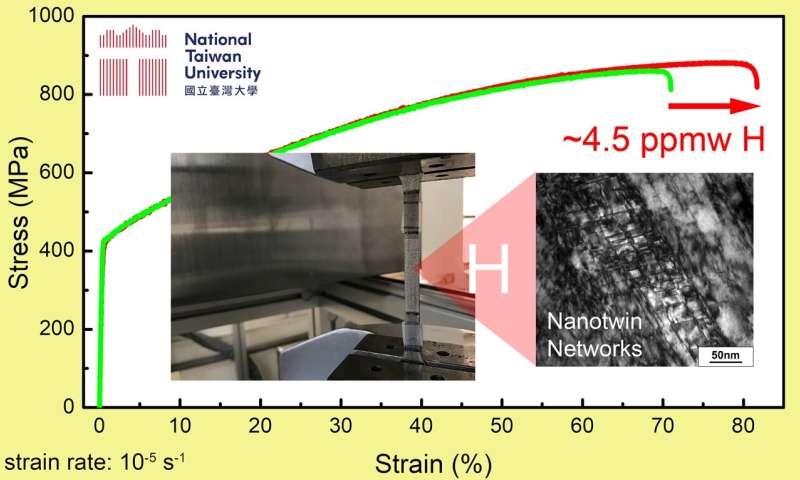

We have developed a lightweight TWIP steel exhibiting high plasticity. The deformation starts with dislocation glide and changes into the TWIP effect. This plastic behavior is enabled by the unique staking fault energy (SFE) and compositional complexity of the steel, i.e., the synergetic addition of Si and Al into Fe-Mn-C alloy. This novel steel is 10% lighter, strong and very ductile. However, being a TWIP steel, it can be expected to be extremely susceptible to hydrogen. Surprisingly, its mechanical properties improve after uptaking some hydrogen.

Zen-Hao Lai, one of the developers of this steel on my team, found that this steel exhibited extra ductility when it was charged with hydrogen. His first thought was that the slow strain-rate tests might have been improperly performed. After successive iterations, we confirmed the new mechanical response to hydrogen of this steel, which we dubbed hydrogen-induced ductilization (HID). We further validated the following characteristics in this new mechanism, as follows:

- The trapped hydrogen is diffusional but not harmful.

- HID is irrelevant to the diffusion of hydrogen.

- The steel shows no signs of brittle fracture.

All these points are entirely contrary to the principle of hydrogen embrittlement. The diffusion of hydrogen in austenitic steel is so slow that the charged hydrogen should be trapped only in the subsurface of this steel. Based on theoretical calculations, the surface concentration of hydrogen can be as high as 500 ppmw. A positive impact, i.e., ductilization, from a high concentration of hydrogen was completely unexpected. We soon identified a critical question: How can hydrogen in the subsurface enhance ductility?

A stacking fault energy of serendipity

The answer starts from the fact that hydrogen is able to reduce stacking fault energy (SFE) or increase twinnability of austenitic alloy, which has been proposed by several research teams recently. However, an appropriate SFE is required for HID. When SFE is low as known in typical TWIP steel, hydrogen eases intergranular fracture under intersections between deformation twins and grain boundaries. When SFE is too high, no ductilization effect is observed and, in some austenitic steels, hydrogen-enhanced local plasticity causes embrittlement.

In this work, published in Scripta Materialia , a special SFE had been achieved. Hydrogen in subsurface reduced local SFE and enabled hydrogen-enhanced densified twinning. Importantly, such twin-strengthened surface retards development of plastic localization, which invokes the typical fracture of this steel. Thus, the deformation can continue to a larger strain without much change in global work hardening behavior. The SFE of this steel is 49.5 mJm-2, a value of serendipity making HID occur. Therefore, HID is an inevitable outcome when compositional complexity was designed for this novel lightweight steel.

Hydrogen makes steel better under twinnability engineering

In summary, elaborate twinnability engineering with an adequate SFE not only prevents HE but brings about extra ductility, i.e. HID. To prevent HE for TWIP steel, a common method is to increase SFE by adding aluminum (> 2 wt. %). However, a positive role of hydrogen is for the first time claimed in TWIP steels. By twinnability engineering, we recently invoked HID in high-entropy alloy manufactured by selective laser melting in an unpolished work. Additionally, some similar ideas were also found in other austenitic alloys such as Fe-Al-Mn alloy, high-entropy alloy and stainless steel.

Safer, stronger, lighter and cheaper alloys for hydrogen storage and transportation are critical to net-zero society. Twinnability engineering blazes new trails toward advanced high-strength steels for storage of liquids or gaseous hydrogen. We now attempt to derive a model to predict the occurrence of ductilization. Moreover, we hope this new principle could accelerate materials development for hydrogen energy and economics.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Zen-Hao Lai et al, Hydrogen-induced ductilization in a novel austenitic lightweight TWIP steel, Scripta Materialia (2022). DOI: 10.1016/j.scriptamat.2022.114629

Hung-Wei (Homer) Yen is an associate professor in the fields of metallurgy and micrscopy at National Taiwan University. He leads the Microstructure and Defect Physics Group at the Department of Materials Science and Engineering, and his research interests include microstructure and defect, phase transformation, mechanical behaviors, electron microscopy and atom probe tomography. He has published more than 100 SCI papers and given more than 30 talks in the field of microstructure-property relationship in steels, titanium alloys and high-entropy alloys. He owns eight patents about the developments of advanced alloys, particularly related to alloy design and process control. The research activities of his group are distributed across the U.S., China, Germany, the U.K. and Australia. Material solutions to hydrogen is his recent focus.