Slippery coating fends off frost while being kind to the environment

Before we get our hands full of formulas and formulations, let's begin with "A Song of Ice and Fire."' Adapted from George R. R. Martin's novels of the same name, there's a riveting sequence in HBO's water-cooler show "Game of Thrones."

As the protagonist Jon Snow and his band of brothers venture upon a wight-hunting winter retreat, risking the national security of the mythical land of Westeros, they are stranded in a polar vortex and surrounded by the Night King's cold army. Having received a save-our-soul signal, Daenerys Targaryen, dragon mom and Jon's aunt, arrives at the venue leading her fiery dragons ex machina.

What follows is an antiseptic battle between the living and the dead, whereby Dany's dragons torch the marching freezing front in a signature move of fire and fury. As the triumphant Dany prepares to leave, the Night King kills one of her dragons in a one-hit knockout using an ice spear thrown with an Olympic-style accuracy. In a dramatic turn of events, all very Night King-esque, the fiery behemoth is later transformed into a frost-breathing ice dragon to spread winter even faster: Fire = 0, Ice = 1. Be it in the mythical North of the Wall or North America, the woes of icing and frosting are longstanding.

Come winter, nature drapes the surroundings in a white blanket, immensely diverse yet infinitely monochromatic. But there's more to this pristine icy beauty, with the menace of ice or frost formation on functional surfaces afflicting various industries, engendering economic losses of billions of dollars around the globe.

For example, the freezing of supercooled water droplets on aircraft wings leads to heavy ice accretion altering the in-flight aerodynamics and posing a severe challenge to its operational safety. In addition to annoying flight delays during the Christmas holidays, icing has been estimated to account for 9.5 percent of fatal aircraft accidents. The most tragic one is the crash of Arrow Air Flight 1285 in 1985, killing 256 people aboard. Icing and frosting also affect the performance of wind turbines, thermal management systems, building infrastructure, and telecommunication systems.

Quite naturally, over the years, considerable efforts have been directed into developing engineered surfaces that impede ice formation or have low ice adhesion on the surface. The majority of these conventional techniques to prevent surface icing in cold winters rely heavily on the use of liquid deicing chemicals that need to be applied in thousands of gallons. However, being liquid, they are quickly dissolved or depleted, demanding frequent reapplication. Needless to say, it has a significant toll on the environment and economy.

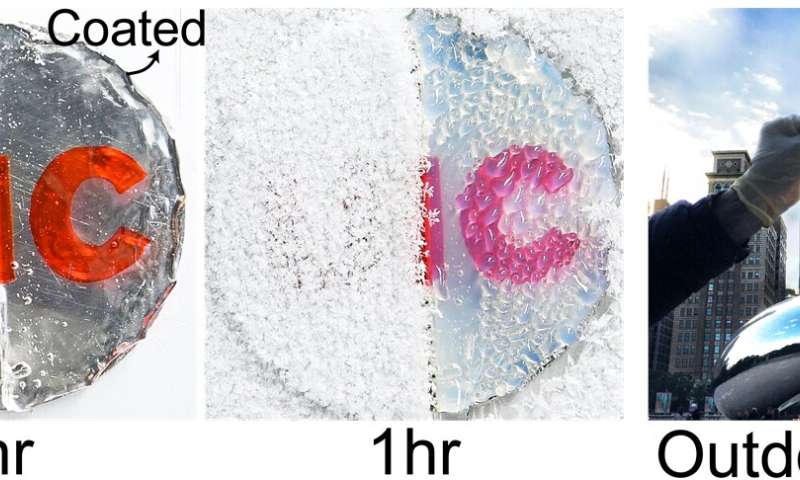

How about addressing this chilly issue by using materials that are solid when cold and can hold off frost for hours? The latest research paper from our group at the University of Illinois Chicago, for which I am the lead author, addresses this burning issue by devising an extensive library of more than 80 bio-friendly phase change material (PCM) based formulations. These materials have a melting point higher than the freezing point of water, with the capability of remaining in a solid state away from the condensing droplets but switching to a liquid state in their immediate vicinity by trapping the latent heat released during condensation and thereby preventing drops from freezing for an extended duration.

To put it simply, the very humid environment which summons the cold army of frost can be used to arrest it. The functional coatings prepared from these PCMs function on a principle of leveraging thermoresponsive properties, by virtue of which they can create an in situ generated slippery surface layer. The self-lubricating liquid layer provides a protective barrier between the underlying substrate and a variety of foulants, ranging from ice to disease-causing bacteria, preventing them from establishing a strong foothold. In addition to exceptional frost resistance, the coatings are endowed with beneficial functionalities of optical transparency during environmental precipitation like an ice storm, high shear flow stability under abrasive conditions, and self-repairing characteristics upon being mechanically damaged. With this versatile portfolio of fascinating functionalities, all integrated into a single material system, we envision the developed compositions will find extensive real-world usage in the energy, transportation, healthcare, and military sectors.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Rukmava Chatterjee et al, A Family of Frost‐Resistant and Icephobic Coatings, Advanced Materials (2022). DOI: 10.1002/adma.202109930

Rukmava Chatterjee is a Ph.D. student at the University of Illinois Chicago with industrial-academic experience (10+ years) in thermal management, material science & mechanical design, trained to solve challenging scientific problems.